August. It’s nearly time for the nationwide fireworks competition ‘Omagari no Hanabi’ (Omagari Fireworks). This is the leading fireworks competition in Japan, with the nation’s number one fireworks experts all gathering together in Omagari in Daisen City. It is said that some 700,000 people come to visit from all over Japan in anticipation of seeing these master pyrotechnicians at work. As the competition draws near (held on Saturday, August 27th 2016), it’s time to find out a little bit more about the job of a ‘hanabi-shi’ involves. ※This is an article that was written in last summer, 2016.

Written by Fumiko YABUKI

Editor; former designer. Born and raised in Akita, she is a hardcore Akita native! She is Deputy Chief Editor for the free magazine “non-biri”.

Photographs by Yōma FUNABASHI・Nozomi TAKAHASHI

Our lecturer today is Mr. Kentaro Saito from Hibikiya Co., Ltd. , a fireworks manufacturing business in Omagari, known as ‘Fireworks City’. At this time of year, there are fireworks festivals every week all over Japan. Today we are visiting Mr. Saito’s fireworks factory, where all the staff are hard at work, so he can show us how his fireworks are made.

- Saito

- The process for making a firework can be broadly divided into four stages: 1) Mixing the powder or ‘milling’ 2) Granulation – making pellets of fireworks powder (we call these ‘stars’) 3) Loading the firework shell with the pellets 4) Finishing off by pasting the shell. Today, we’re not going to be doing the first stage (mixing the powder), so I’m going to start showing you how to make a firework from the granulation stage, okay?

- Yabuki

- Sounds good. Thanks so much for showing us round the factory!

Granulation

- Saito

- First, we make the filling for the fireworks shells. Making the firework stars, as we call them, is a bit like making little balls of candy. We start by filling the drum with little ceramic balls, like granules, smaller than sesame seeds. We add a little water to the mixed powder to loosen it. We add a bit more powder and then let it dry. We do this three or four times and gradually the stars grow in size.

- Yabuki

- Wow!

- Saito

- One of the features of Japanese fireworks is the way they change color. At this stage I don’t know what color this is, but I’m adding some blue firework powder now and then red…just like this. Then I add more liquefied powder, little by little.

- Yabuki

- Is this a traditional way?

- Saito

- That’s right. Originally, this was all done by hand, but in the last 30 years or so, we’ve started using drums like this. In terms of the firework-making process, this is the only part that we use a machine for. If you try to do everything in one go, the mixture gets too wet, it won’t light, and the mixture falls apart. So you have to do it little by little, gently and slowly.

- Yabuki

- Even though you’re using a machine for this stage, this mainly looks to be a manual job!

- Saito

- I check the size of a firework using this wooden box, which measures around one ‘shaku’ and two ‘sun’ in length. (‘Shaku’ and ‘sun’ are traditional units: shaku is approximately 30cm; and sun is 3cm.) I can work out the size of a firework by how many of these pellets I can line up inside.

- Yabuki

- I see. The box is your basic standard, right? You can tell how big or heavy a firework is without actually measuring it.

- Saito

- These pellets were much smaller to begin with. They’ve grown in size. To make a 3cm-sized firework like this takes around a month.

- Yabuki

- What! Seems like a lot of effort for something that goes up in a flash!

- Saito

- It actually takes a month and a half to make a ‘shaku-dama’ (a 30cm shell). When you launch it, it’s alight for around six seconds.

- Saito

- We dry the stars in this drying room.

- Yabuki

- My goodness! It’s like a sauna in here!

- Saito

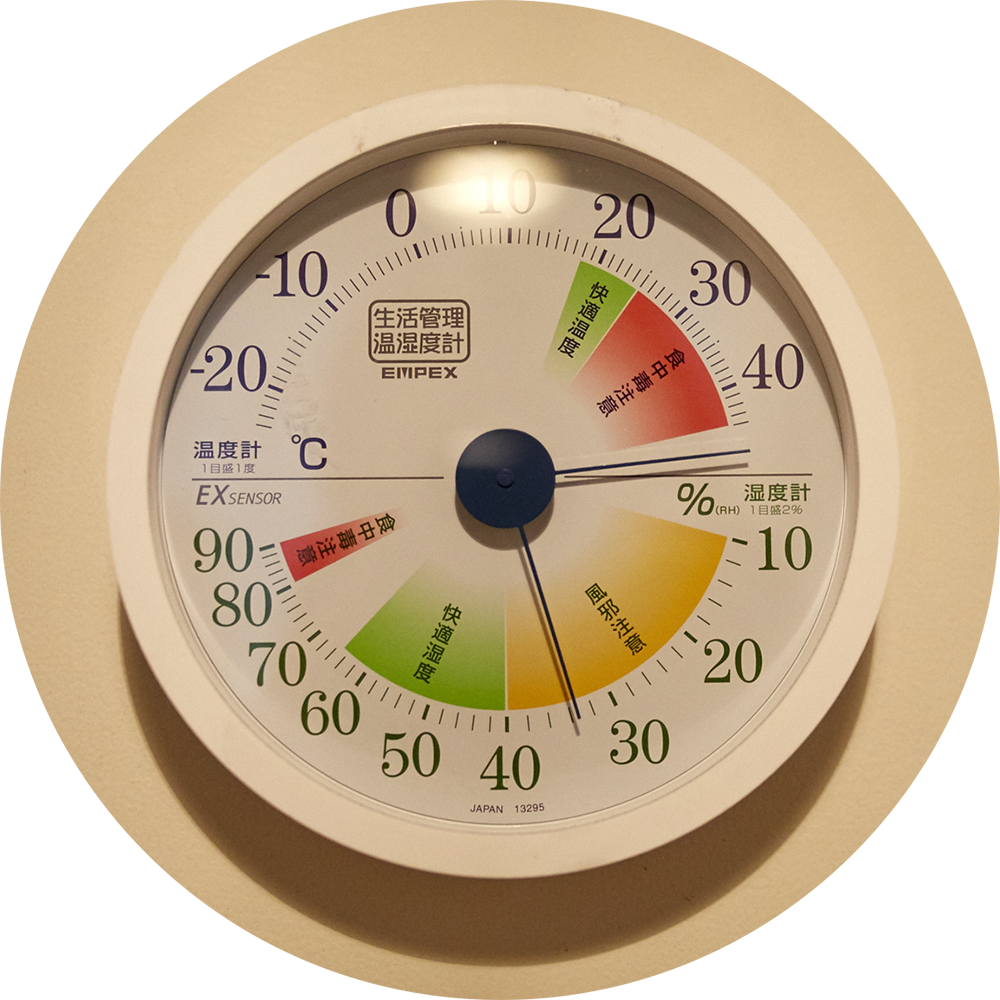

- I can tell you that at the moment the temperature is over 40 degrees.

- Yabuki

- I can’t believe how you manage not to faint.

- Saito

- It would be better if we could dry the stars naturally in the sun, but the weather is too unreliable. We put them in here to dry, then we put them back in the drum and mill them … and then repeat the process. We can’t use fire to heat the room, so we use hot water.

- Yabuki

- I can tell you’ve put a lot investment into these facilities. It must have been really tough in the old days.

- Saito

- It certainly was. Without facilities like this, we wouldn’t be able to work the way we do. You know I need 400 liters of kerosene a week for the drying room.

- Yabuki

- Really?!

- Saito

- This is called the charge, used as ‘burst’ to propel the stars through the air. There is fireworks powder in this, but the core is made of husks of Akita Komachi rice.

- Yabuki

- You’re kidding! Is it because we produce so much rice in Akita!

- Saito

- In Akita and Niigata, we mainly use rice husks. We use them for shells of up to 15cm. For the bigger shells, we mix in cotton seeds picked from raw cotton. If there is no rice available, you can use cork. I’ve tried it in the factory here, but it doesn’t make the stars fly through the air as effectively as rice husks.

- Yabuki

- That’s the power of Akita rice for you!

Loading the firework shells

- Yabuki

- This is where you load the shells, isn’t it?

- Saito

- Right. We’re loading 21cm shells at the moment.

- Yabuki

- How many years would it take you to learn how to load shells like this?

- Saito

- At our factory we’ve got a few old hands, as well as people who have only been here a year doing this. But to get to be really good at it would take you at least five years. The person loading these shells is Konno. He’s been here for eight years. He’s the most skillful of the younger workers here.

- Yabuki

- What colors will this firework make when it’s launched?

- Konno

- It will light up in a perfect circle. The colors will change – silver to start with, then pink, and then orangish color called ‘nanohana’ (canola flower).

〈See Konno expertly loading a firework shell here〉

- Konno

- That’s it. All done!

- Yabuki

- That’s great! Thank you for showing us! Looks like you’re pretty good with your hands!

- Konno

- I think there’s a dirty joke in there somewhere! Yes, it’s all about hand movements! (Laughs)

- Yabuki

- That’s kind of what I thought! (Laughs) There’s some writing on the shell, isn’t there? What does it say?

- Konno

- This is the color sequence. ‘Gi’ for ‘gin’ (silver) to start, ‘Pi’ for pink, ‘Na’ for nanohana (orangish yellow). The words are abbreviated, but we can tell what color the letters stand for.

- Yabuki

- I get it! Silver first, pink, then yellow.

Pasting the shell

- Saito

- After loading the shell, we finish the firework off by sticking paper onto it. This is called ‘pasting’.

- Yabuki

- So you paste on several layers of paper, right?

- Saito

- Sure. For a big shell, we’ll paste six sheets of paper for each layer. After sticking on six sheets, we let them dry, then paste on another six sheets. We do this ten times, so that’s 60 sheets of paper altogether. Once it’s all dry, the firework is ready.

- Yabuki

- What’s the point of pasting?

- Saito

- The pasting process strengthens the shell. When it explodes in the air, the pressure applied makes the stars fan out in a circle. Depending on the number of layers pasted on, and how strong or fragile the shell casing is, this is what ensures the stars fan out in a circle. It’s a vital part of the process.

- Yabuki

- This really requires a deft touch, doesn’t it?

- Saito

- You’re right. I’d say that fireworks made by these guys are the best fireworks in the whole of the country. We also bring the pasted shells into this room to dry.

- Yabuki

- Ha ha! They look like melons! They’re huge!

- Saito

- These are ’10-go’ fireworks (30 cm). One of these will shoot up 320 m into the air, with a burst area of 320 m.

- Yabuki

- I can’t believe something this big goes up so high! How much does it weigh?

- Saito

- It depends on what’s inside, but this one’s about three to four kilos. Depending on the contents, it could be as much as 10 kilos. A 60 cm shell will weigh around 60 kilos.

- Yabuki

- 60 kilos!

- Saito

- It’s hard work bringing these shells in and taking them out again. The warm air only comes in from one direction, so our staff have to keep coming in every hour to change the shells’ positions. You can feel how hot it is…

- Yabuki

- My goodness! That’s tough!

- Saito

- This guy joined us in April. When he started, he weighed 60 kilos. Now he’s down to 55 kilos!

- Yabuki

- You’re kidding! This job takes real dedication, I can see that. Thanks so much guys, be careful not to pass out…

These fireworks light up the whole of the night sky in brilliant colors. It’s been amazing to how much hard work and effort goes into making them. Next time, we’re going onto the factory floor to find out more about lighting and launching these fireworks.

2. Working as a ‘hanabi-shi’ (fireworks master/pyrotechnician) >>